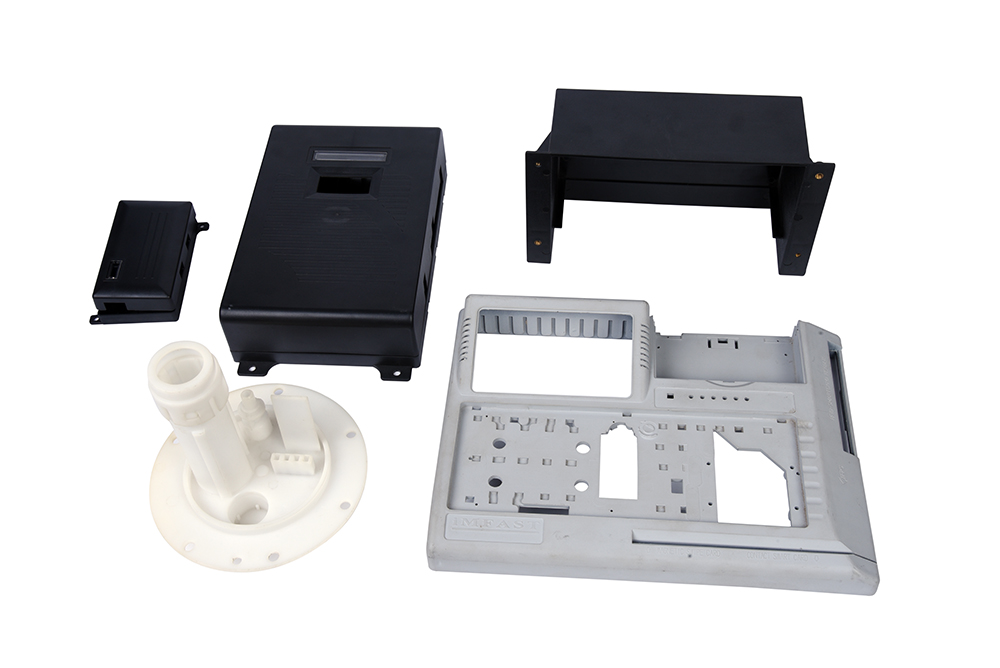

Sole Focus on Plastic Engineering.

Fortune Plastic Technologies Advantages

1

2

A one-stop shop for custom moulding solutions.

3

Synchronization with supply chain.

4

Well-Maintained Quality Management Systems (QMS).

5

Design & Development (Sketch &Part) capabilities.

6

Tool Room Facilities.

7

Experience of serving diverse Industries.

8

Expertise to process a wide range of engineering plastic.

9

Carry out post moulded activities –labelling, Hot stamp welding, printing, chrome plating.

10

ISO 9001:2015 certified company.

1

Sole Focus on Plastic Engineering.

Our dedication towards business of Plastic Engineering is distraction free. Over the years, we did not digress into lucrative opportunities if it did not align with our first and only passion – Injection Moulding.

2

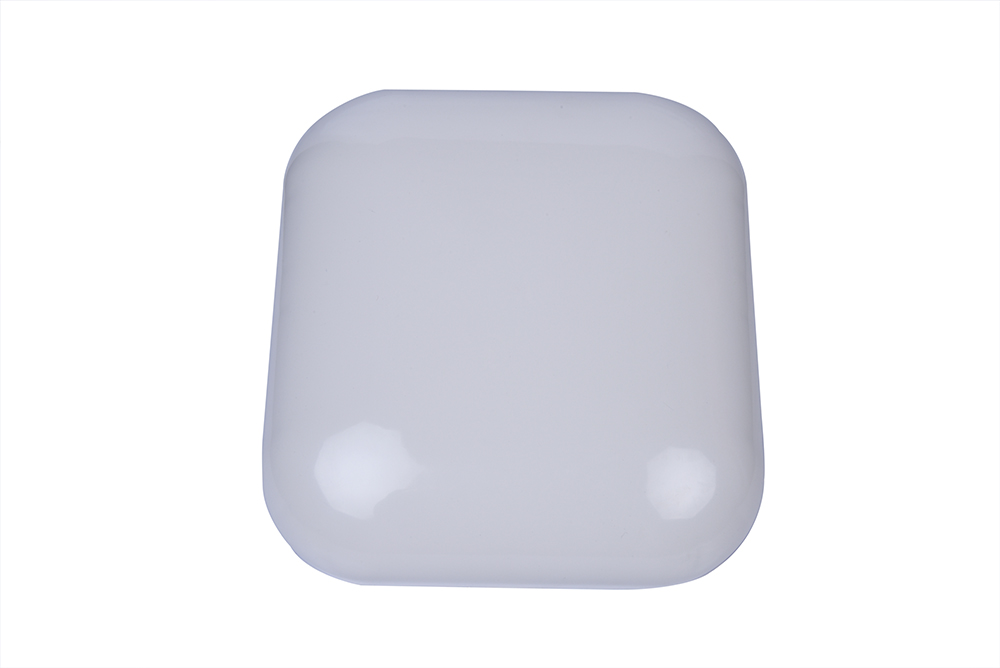

A one-stop shop for custom moulding solutions.

Having all aspects of manufacturing under our total control allows us to deliver quality consistently round the year. All aspects, right from design to finishing is our key differentiating factor.

3

Synchronization with supply chain.

Just-in-time delivery is our key to achieving operational efficiency and we assist our customers in achieving this by synchronizing our supply line with the production chain. Schedules are matched, logistics are set in motion and processes are set that ensure that we remain reliable supply chain partner.

4

Well-Maintained Quality Management Systems (QMS).

QMS systems with ownership & authority at the operator level (mistake proofing). This is backed up by in-house inspection and testing assurance systems. We are close to achieving Statistical Process Control and moving with a steady pace towards Six Sigma levels, we also conform to ISO 9001:2015 complied.

5

Design & Development (Sketch &Part) capabilities.

The upside of having the entire process under one roof results into a key differentiator. We can offer Art-To-Part service that is seamless and speedy, powered by our in house CAD/CAM tools.

6

Tool Room Facilities.

Machining of the Injection Moulding tool is a vital part of the design cycle. While many custom Injection Moulding companies outsource this activity and thereby lose the opportunity to gain control over finer aspects of Quality, we pride ourselves on having this in-house capability.

7

Experience of serving diverse Industries.

We describe ourselves as being Industry agnostic. We have provided solutions to customers across Fluid Engineering, Automotive, Industrial, Medical, Electronics & Electrical, Home Appliance, Defences, Water Treatment to name a few.

8

Expertise to process a wide range of engineering plastic

Fortune Plastic Technologies utilises the latest injection moulding technology, materials handling to provide top quality precision plastic parts to a range of industries.

9

Carry out post moulded activities –labelling, Hot stamp welding, printing, chrome plating.

10

ISO 9001:2015 certified company.

Testimonials

Having all aspects of manufacturing under our total control

Madhusudan T S

CEO

Our dedication towards business of Plastic Engineering is distraction free.

Madhusudan T S

CEO

Just-in-time delivery is our key to achieving operational

Madhusudan T S

CEO

Have a question?

fortuneplasticco@gmail.com,

madhusudan@fortuneplastictech.com

sales@fortuneplastictech.com

Address

14, TC Palya Cross Road, Thambu Chetty Palya,

Battarahalli, Bengaluru, Karnataka 560049

Phone

+91 98450 56844